He already had a taste for development, acquired during his first job after graduating from college in the early 1990s, when he worked with an environmentally conscious, single-family home developer involved with non-profits.

Ansin grew up making shoes in the Anwelt Shoe Factory in Fitchburg, a town located about 50 miles from Boston and noted for its Victorian architecture. After 20 to 50 years of downward spiral, the town that formerly relied on the paper industry had become a bleak, industrial wasteland and the shoe factory an obsolete white elephant. Thinking he might inherit the old Anwelt mill structures, Ansin wondered if they might be ready for a new life. But he never dreamed the transformation of the underutilized industrial building into an environmentally friendly mixed-use urban campus would be the springboard to a new career and the formation of a smart-growth development company called MassInnovation.

Fast forward to 2007, and the MassInnovation Center in Fitchburg that houses office space for community organizations and a charter school is beginning its third phase, the 90-unit Anwelt Heritage Apartments for seniors–and MassInnovation is pre-selling units in the initial phase of a $200 million redevelopment of another aging mill located 40 miles away in a run-down area along the Merrimack River in Lawrence. When complete, the project dubbed Monarch on the Merrimack will bring a total of 800 luxury loft-style condos and six floors of retail space to the city.

Cleaner, cheaper, greener

The Fitchburg project is powered by a combination of geothermal wells and solar photovoltaic arrays, and Ansin is employing those same technologies at Monarch. The use of recycled and sustainable materials has earned him a reputation as a green builder, a skill he mastered through trial and error– a process he considers his MBA. “I didn’t know the terms smart growth or green building. I came to those practices as a way to make economic sense,” said Ansin.

His first Aha! moment came in 2000, when Ansin was trying to make the numbers work on Fitchburg. He’d promised to put together a business plan for his father, who still owned the mill and agreed to invest in the project. “I moved into the building, took an office that hadn’t been occupied for 30 years, found an old wooden desk and went to it. I presented my dad with a two-inch thick business plan, but he just sat on it. I figured he wasn’t getting back to me because the numbers I gave him weren’t cutting it,” said Ansin. He went back and sharpened his pencil.

After comparing redevelopment costs with projected rents and price points, Ansin realized the only thing he could change in that analysis was the cost of redoing the buildings. He fired the general contractor, bought some used construction equipment and a CD ROM from OSHA about construction safety, and hired a 15-person crew. “We’d been told by the former contractors that the biggest single piece of the redevelopment was taking down and removing certain structures to make way for parking, a campus and green space. They priced this out in their pro forma at 10 percent of my budget,” said Ansin.

But he saw the value in each old brick and beam in the original buildings that date from 1855 and, instead of paying $250,000 to have the venerable structures demolished, loaded on trucks and removed to a landfill, Ansin and his crew took them down piece by piece, salvaging 85 percent of the materials. When he compared the total cost of the three-month demolition process to a conservative wholesale value of the materials he’d saved, Ansin realized he’d found the key to making the numbers work. “We actually made money and I realized it would have been a bad business decision had we redone it the way the experts told us to,” he said. Economic sense is a recurring theme for Ansin. “In the spirit of saving money, we salvaged a tremendous amount of material and in doing so, I learned that people don’t want to walk into an old building and see sheet rock,” said Ansin.

Another deviation from the experts’ recommendations was swapping the originally planned HVAC systems (the cooling tower alone would have cost $500,000) for what is the largest geothermal heating and cooling system in New England (the system at Monarch will be larger than the one at Fitchburg). The use of a geothermal exchange system powered by wells drilled to where the underground temperature is 55 to 60 degrees year round was suggested by Ansin’s friend Matthew Bovenzi, president of Commonwealth National Drilling. When Ansin discovered that the Environmental Protection Agency and the U.S. Department of Energy proclaimed geoexchange to be the most efficient, inexpensive and environmentally friendly way to heat or cool buildings, he went with his friend’s idea. Bovenzi’s company sank twenty-six 1,500-foot wells for the Fitchburg project, and plans to drill a total of sixty for the Monarch–thirty to be utilized in the first phase, 20 for the lofts and 10 for the commercial space.

Green funding

Soon Ansin was contacted by a state agency that caught wind of the smart-growth guy redeveloping the old mill in Fitchburg. “They said, ‘We have a $200 million fund called the Renewable Energy Trust Fund and we’d love if you would consider applying for some feasibility money to perhaps do some solar,'” Ansin said. He applied, received $50,000 and hired Harvard-based Solar Design, the architect that designed the solar array on the White House. He got another $500,000 stipend from Mass Technology Collaborative to place an elaborate generating plant on the roofs. Then, just as MassInnovation was ready to pull the trigger on the installation, another $500,000 in

financing came in the form of a matching grant from the U.S. Department of Agriculture’s renewable energy program.

“I found you could use the local and state government grants as a match, so we used the $500,000 from the state and got a match from the Feds and built the largest solar photovoltaic panel system in New England on this mill in one of the worst neighborhoods in Fitchburg,” said Ansin. Half the array is built on trellises made of materials recycled from the mill itself.

Ansin’s star was rising. “I got a call from a broker at Cushman & Wakefield who said, ‘You’ve got to come to Lawrence because we are listing what is the largest mill in the world,’ and my first response was, ‘Get out of town!'” said Ansin, whose perception of Lawrence was that it vied with Fitchburg for which one had the worst reputation. Lawrence has been called the arson capital of the country, the auto- fraud center of the nation and a place where businesses go to die.

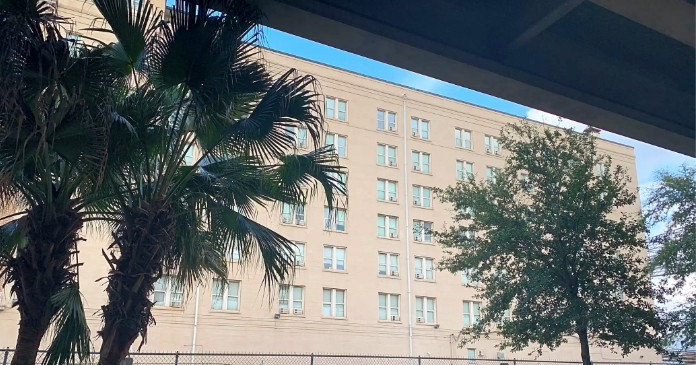

But Ansin went anyway, in the summer of 2003, and fell in love with the 1,600-foot-long (almost one-third of a mile), 1.3 million sq. ft. red brick Wood Mill that, when it was built in 1906, was said to be the largest textile plant in the world and dubbed “the eighth wonder of the world.” With little investor competition, Ansin bought the building for $4.4 million, or $3.30 per sq. ft., and found that “all the things I was struggling to do and having success with in Fitchburg seemed so much easier in Lawrence,” he said.

One reason is location. From atop the Wood Mill building that contains nearly 30 acres of space under one roof, Ansin gazed on the Merrimack, and the sheer size and force of the river made what he was fond of calling the raging Nashua in Fitchburg seem small by comparison. And, looking past I-495, he could almost see Phillips Andover, the prep school his father attended in one of the state’s wealthiest communities.

“I thought, here I am in Lawrence, in an overlooked community right next to all this wealth, and my vision was to take what we’d started in Fitchburg and hone it to the next level,” Ansin said. He decided to break the property into sections separated by firewalls and convert it over time in a demand-driven way to create a vibrant city- within-a-city that would take advantage of the historic downtown, the river and the canals. Lawrence rolled out the red carpet.

Mill history

The Wood Mill that MassInnovation plans to transform into an urban live/work/play community plays a prominent role in the history of the city. It was built by William Madison Wood to house The Woolen Trust, which merged textile mills in Lawrence with mills in upstate New York and was incorporated as The American Woolen Company (AWC) in 1899, two years before the concept of corporate trusts was introduced by J.P. Morgan. Wood began working in the mills at the age of 12, rose through the ranks and eventually married into the family of mill owner Frederick Ayer and became a multi-millionaire at the age of 41. He built another mill across the street called the Ayer Mill, which houses a clock tower second in size only to Big Ben. By 1921, AWC owned and operated nearly 60 mills and storehouses in 39 locations in eight states.

Until the 1950s, the mills held center stage in Lawrence, which was founded in 1845 by a group of investors who built the largest dam in the world to harness the power of the Merrimack River for industry. The Bread and Roses Strike of 1912 began in the mills of Lawrence when the Massachusetts state legislature reduced weekly hours for working women and children to 54 from 56. The strike began when workers opened their pay envelopes to find they had been paid for two hours less. To appease the strikers, Wood cut work hours to the legally allowed 54, but workers claimed they had to work harder to produce the same in less time because the looms had been sped up to avoid losing profits.

Wood finally settled with the strikers, but when explosives were found in the mill and a contractor under his employ confessed to having placed them there, Wood was indicted for conspiracy to destroy the mills. After a long trial that resulted in his acquittal, Wood moved to Shawsheen Village, Mass., where he established a community for his executives. He suffered a stroke and retired to Florida in 1926. A month later, Wood killed himself with a revolver.

The textile industry prospered during the First World War, but the mills fell into disuse after World War II. Half the Wood Mill was torn down and paved over for parking to be used by such companies as Honeywell Bull from the mid-1950s to the mid-1990s and Malden Mills Industries, which took over a portion of the building in 1995 after a huge fire destroyed some of the original Malden buildings. But what remains today of the Wood Mill still is 500 feet longer than the Empire State building is tall.

Everything old is new again

Today, the 10 million square feet of mills that line the river and both sides of the North and South canals are at the center of a massive revitalization effort in Lawrence. And, Monarch on the Merrimack, named to reflect the emergence of the city’s historic mill district from its sleepy cocoon, is just one of the exciting projects taking place there. Just last year, the federal and state governments built a $25 million regional transportation station across the street from Monarch on land MassInnovation sold to the Merrimack Valley Regional Transit Authority. The station serves light-rail along the Haverhill line with a 900-car parking deck, a bus depot and a limo service to various airports. As compensation, MassInnovation owns the top two parking decks.

Chet Sidell has been one of the biggest investors in the mill district over the past 20 years and the number of developers looking to take part in Lawrence’s metamorphosis continues to grow, thanks in part to a marketing campaign by the city that includes developer incentives, a nationwide mailing and a Web site with an interactive list of available properties. Today, there is a waiting list to get in on the action.

Other developers milling around Lawrence include local pizza magnate Sal Lupoli, who bought 1.4 million sq. ft. of mill space on the Merrimack River and developed a seven-story commercial building called Riverwalk that houses a daycare center, a children’s museum and the 45,000 sq. ft. corporate headquarters of the Merrimack Valley Credit Union. Over the past few years, the Everett and Stone Mills also have seen some renovation by owner Bert Paley.

The Architectural Heritage Foundation, a Boston-based nonprofit, along with the Bank of America Community Development Corp., is converting one of the Washington Mills buildings into 155 loft-style rentals for artists. Units range from 625 to 1,700 sq. ft.

And, at the 100-year-old Malden Mills, where Polartec fleece was manufactured before moving to a new complex, seven outbuildings are being converted to housing by Winn Development. The first of three phases, which calls for 86 units of mixed-income apartments, received $5.3 million in debt financing from MassHousing, the state’s affordable housing bank. Winn requested an additional $1 million from the Affordable Housing Trust Fund and the use of Low Income Housing Tax Credits, and federal and state historic tax credits and anticipates receiving $500,000 in HOME or Community Development Block Grant funds from the city of Lawrence for the project.

Ansin declined the use of historic tax credits and any other subsidy that would have required the residential component of Monarch remain rental for five years. He did receive $2 million in 10-year Tax Incremental Financing (TIF) for the commercial component, which equates to a $227,411 tax exemption in the first year and declines to $178,811 by the tenth. That tax break will be offset by $1 million in taxes the city expects to receive when the condos are completed and sold.

Ansin isn’t out to create affordable housing. He thinks there are enough affordable units in the state. “What people need most in Lawrence is equity from homeownership. The average two-bedroom apartment here rents for $1,200. If Monarch was built as rental, tenants would rent as the property appreciated and get gentrified out in five years when the rentals were sold as condos to people from the suburbs,” said Ansin.

But he doesn’t see a lot of families moving to the Monarch. The project is popular among echo boomers and empty-nester baby boomers, both of whom are plunking down deposits for the 202 units in the first phase that range in price from $200,000 to $1.5 million. They are attracted by the 16-foot ceilings, 13-foot-high windows with 48 panes, brick-and-beam interiors with open duct work and wood or concrete floors. Units range from 900 sq. ft. studios to two, 6,000 sq. ft. private residences that soar above 30 split-level 2,100 sq. ft. penthouses with 1,000 square feet of deck space. Some ground level units include fenced-in garden spaces adjacent to parking. And, to grab the attention of the 20-somethings, Ansin asked the popular Indie band, Freezepop, to design three studio units in conjunction with IKEA.

The first phase began pre-selling last November with completion scheduled for next October. “Our goal was to have 10 percent purchase and sales when we started construction and we exceed that now,” said Ansin. With MassInnovation’s in-house marketing group running open houses seven days a week, roughly 50 percent of the units are either under contract or reserved. Buyers are able to put down $500 to hold a unit for 14 days, after which a five percent at-risk deposit and a guarantee to close at time of delivery is required. Buyers also must agree that their unit will be owner-occupied and, if they sell within the first six months of ownership, Ansin gets first right of refusal.

Two subsequent phases in the Wood Mill building are planned for 300 units each, and a fourth phase of between 20 and 50 historic-looking town homes along the river will be new construction. Five acres of green space will grow in the footprint of half the original building that was demolished and buried under cement, and a 100,000 sq. ft. commercial section that will house an independent movie theater, a bakery and an international newsstand will be topped by a 7,000 sq. ft. green roof and cafe.

Ansin says the geothermal system planned for Monarch is expected to lower heating and cooling bills to around $50 a month for a 1,200 sq. ft. unit–an estimated nine percent savings over a typical air conditioning bill and 32 percent less than the cost to run an average furnace in winter. The use of solar energy to power the geothermal generators will reduce the HVAC costs even further.

Because green is the color of sustainability and also the color of money, Ansin thinks eventually green will go mainstream. “They won’t call it sustainable anymore. It will just be the way they build,” he said. Ultimately, Ansin would like to take his form of development to other places in the world that are in the midst of manufacturing booms, places like China and Brazil. But in the shorter term, chances are he’ll be doing more in Lawrence and other Massachusetts cities. Urban planning professionals and government officials visit his office regularly, seeking his expertise. “I came at the right time with the right background to see the right opportunity. I look more visionary because things here are happening so fast. The harder I work, the luckier I am,” said Ansin.