Changes are coming in January that will impact multifamily developers and owners looking to install or upgrade their HVAC systems. Every six years, the Department of Energy (DOE) re-analyzes the effects of energy usage, sets minimum requirements for equipment and manages testing standards by which product efficiencies are measured.

The DOE is increasing the minimum efficiencies for central air conditioners and heat pumps in 2023 and changing the testing procedures for determining those product’s efficiencies, predicting that implementation of the new standards will save $2.5 to $12.2 billion in energy bills in 30 years and provide cumulative reductions in greenhouse gasses.

The regulations that vary by region require an increase in Seasonal Energy Efficiency Ratio (SEER), a measure of a systems cooling performance, to no less that 14 SEER for residential systems in the northern part of the nation and 15 SEER in the southern region.

They apply to all new residential central air conditioning and heat pump equipment based on installation date. In the northern region, any 13 SEER AC built before January 1 can still be installed on or after the deadline. But in the southeast and southwest, any AC product that does not meet the requirement cannot be installed after the January deadline.

A refrigerant change also is coming down the pike, with the EPA discontinuing the use of the current refrigerant R-410-A in new equipment on January 1, 2025.

Meanwhile, manufacturers must redesign all system components by January 1, even if they meet current SEER ratings. Matching components like furnaces and air handlers must be redesigned to meet changes in airflow setpoint and, depending on region of installation, additional field install equipment, such as thermal expansion valves may be required.

“The minimum increase in efficiency of what we can sell is going up across the country roughly a SEER point and, as that bottom goes up, the market will follow,” said Tim Brizendine, director of product management at Lennox International, Texas-based manufacturer of heating and cooling products.

“We are preparing for that and over the past year, Lennox went from a maximum of 26 SEER to a max of 28 SEER, trying to keep efficiencies up on the cooling side, as well as on the heating side,” he said.

The changes center around efforts to decarbonize buildings, which today generate nearly 40 percent of annual global CO2 emissions, which climate specialists blame for global warming. But reducing apartment building emissions is challenging and solutions may carry significant upfront costs and uncertain savings.

Right sizing right equipment

Choosing the wrong HVAC system for new construction can lead to a number of issues that increase a developer’s overall budget or cause maintenance problems later on.

“HVAC systems typically are chosen for new construction based on building layout and design, while retrofits are usually limited to replacing the type of system that was already in the building with a same type system of higher efficiency rating,” said Brizendine.

Most important is choosing the right size system for the space, he said. Furnaces are measured in British Thermal Units, or BTUs, which is the unit used to measure thermal energy. Air conditioners are rated in tons, with a single ton of nominal cooling equaling 12,000 BTUs.

An oversized system provides a higher capacity in relation to its size, but the system won’t run long enough for dehumidification to occur. Temperature swings prompt it to start up and shut down in rapid succession, resulting in cold, clammy and uncomfortable air. This results in higher energy costs and the continuous starting and stopping, called short cycling, adds wear and tear on the systems components.

Carrier senior product manager Mark Douglas spoke to Yield Pro during the National Association of Homebuilders International Builders Show (IBS) held in Orlando in February, explaining how his company’s ductless system is a good choice for use in apartment communities with smaller units.

“Some smaller apartments are forced to use a 1.5-ton unit because for many manufacturers, that’s the smallest ductless system they make and the comfort level isn’t always as high because its oversized for the space. Our multifamily air handler that has become very popular when used with a single-zone ductless outdoor unit is able to get down to a true one-ton system.

“The unit’s smaller tonnage and BTUs ramps down to almost a third of capacity, so in a one-ton unit we ramp that down to 4,000 BTUs, which is roughly a third of a ton, making the environment more comfortable and using much less energy to achieve.

“It also has a smaller footprint, takes up less space and is less intrusive and light weight, so if you put it on a roof top, you don’t have to consider a heavier structural load for support, which allows for more installation options. In other parts of the world these units often are placed on balconies and, because of their small size, can be four inches from the wall and the blow air discharge away from the apartment and over the balcony and any noise goes with it.

“Doing that cuts the cost of the copper needed to connect the indoor unit with the outdoor unit dramatically and shortens it from 50 feet down to 10 or 15 feet. Another great thing about our ductless systems in multifamily is you can put an indoor head in each room and have individual controls,” said Douglas.

The new designs

More redesigned products are emerging to coincide with the transition to higher SEER ratings ordered by the DOE. Some were showcased by manufacturers at IBS.

Allied Air Enterprises, a division of Lennox International, featured its Magic Pak all-in-one HVAC system that eliminates the need for outdoor equipment on rooftops. These systems provide dehumidified outside air for ventilation and are capable of controlling the temperature in multiple rooms and large areas. Additional costs are required for air terminals and ductwork concealed in the ceiling and a closet or enclosed space on the exterior side is required for unit placement and heat dissipation, necessitating exterior louvres that could affect the building’s appearance.

Allied Air’s equipment is currently undergoing the new testing protocols to meet the January deadline. “These are huge hoops to jump through,” said Allied Air senior marketing manager Scott Shipman in March.

Lennox, which offers centralized and decentralized HVAC systems, including heat pumps, air handlers and accessories, has a full line of single- and multi-zone products.

“We typically use the heat pump in those applications. Both products are very efficient and depending on which part of the country they are being installed in, provide 13 to14 SEER up to 28 SEER for the centralized systems. The ductless mini-splits are variable speed and range from 20 SEER up to 25/26 SEER at this point,” said Brizendine.

Using electricity for heating is becoming the carbon-free choice for many multifamily buildings in the USA. Today, an all-electric building coupled with a renewable carbon-free source of electricity is considered a decarbonized building.

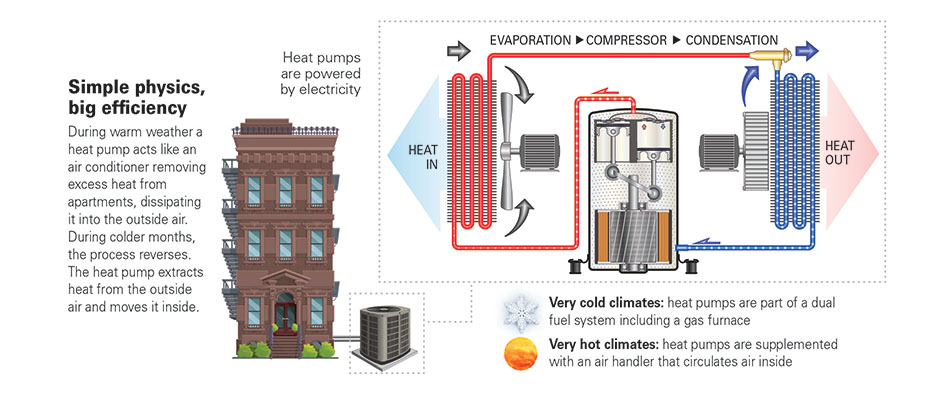

Decarbonizing necessitates swapping gas furnaces, traditionally the equipment of choice for cold climates, with heat pumps. Unlike a boiler or furnace, which burns fossil fuels to produce heat, the heat pump transfers heat through an outdoor unit into the indoor space. It extracts heat from outdoor air in winter but can be reversed in the summer to pump heat out and provide cooling. Exchanging heat in this way is much more efficient that generating it.

Today’s heat pumps use two-stage, or variable speed compressors that allow them to adjust their operating capacity, depending on the situation, to run longer and at slower speed with greater efficiency, while providing more consistent temperatures and greater air filtration.

Lennox pioneered and recently released a low ambient pump designed to work better in colder climates.

“The SL25xPV is the first of its kind. It’s completely electric and efficient down to five- degree to zero-degree temperatures. Its variable capacity compressor drastically minimizes the sound of air kicking on and off inside the units and a special sound dampening system absorbs outdoor noise,” Brizendine said.

“One of the past complaints about electric was that air is not as hot as what one gets from a gas furnace, so now we are not only providing higher capacity, but higher air temperature that gives more comfort in lower ambient conditions,” said Brizendine

Carrier’s Mark Douglas agrees that heat pump performance has increased significantly in the past five to ten years.

“Our unit will produce 80 percent of its rated capacity at minus 22 degree outdoor ambient. We have equipment at 100 percent capacity down anywhere from five degrees above zero to five below zero.

“Capacity diminishes as it starts getting colder, but you’re not going to be in that temperature range all the time, so as long as we were already maintaining temperature, as the temp drops outside we’re going to have a much greater degree of success maintaining closer to that set point than if we wait until it gets cold and then turn it on,” said Douglas.

He explained that a critical consideration with any heat pump in cold climates is to keep it out of the snow, including snow drift.

“So, in our installation manuals, we instruct to install at a height or elevation that’s at least two inches above the anticipated snow line. If you are going against the side of the building you have to account for snow drift, which might be as high as three or four feet, so it needs to be three or feet off the ground at the bottom to keep that out of the ice and snow. Once snow and ice start to accumulate on the bottom, the pumps capacity to heat drops dramatically,” he said.

Carrier’s unit also includes a built-in base pan heater that activates at 34 degrees outdoor ambient temperature. The heater prevents the moisture that is created when the unit goes through a defrost cycle from freezing on the drain pan at the bottom in cold conditions. However, if the bottom of the unit gets covered in snow, it can’t do both. It can’t overcome the snow and the water created from the defrost cycle.

“We also have an air handler that looks like a conventional air handler designed to work with our ductless outdoor unit in terms of the mechanical features required. One of those includes a supplemental heat strip kit that, unlike a traditional air handler, engages when the unit goes into defrost. In our ductless application, in the heating mode, if the system senses, based on the outdoor temperature, that it can’t keep up, it will engage that supplemental heat to get there in cold climate.

“That air handler has been out only a little over a year. We have had many of them installed in Canada, New York, Minnesota and the whole northern part of the country and we have no feedback that they have been not able to maintain in the coldest of winter to date,” he said.

Douglas points out that the price to install or switch to a carbonless HVAC system is comparable to gas. “And, if you add in the cost of the equipment, its less expensive to run an electric heat pump than a gas furnace because you don’t have to run gas line or purchase pipe itself. And, higher efficiencies even at lower ambient offset the operating costs compared to gas,” he said.

HVAC trends

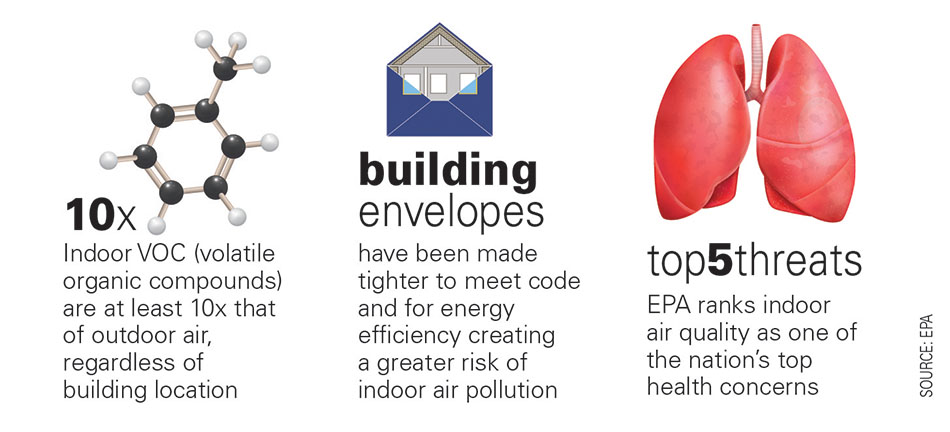

The COVID-19 pandemic highlighted the importance of a healthy living environment, said Lennox International VP and Deputy General Counsel Betty Ungerman. She believes air quality will continue to be a concern among renters.

“I know people who only drink filtered water and I think going forward people will become as concerned about their air as they are about the quality of their water. But one thing to remember is that some of the products that promote air quality also produce ozone, which can damage the lungs when inhaled,” she said.

In fact, relatively low amounts of ozone can cause chest pain, coughing and shortness of breath and can worsen respiratory diseases and compromise the ability to fight off respiratory infections.

“Our products do not produce ozone and they remove any existing ozone in the space,” she said. Lennox has a full line of ventilation product add-ons, energy recovery ventilators, hospital grade filtration standalones and filters.

“Our pure air carbon layer filter removes odors and 16 filters take out dust and debris. The air then goes through a photo catalytic oxidation matrix with a UV light to kill 99 percent of particles the size of viruses,” said Brizendine.

“Efficiency is in our DNA,” said Ungerman, “and while Lennox was probably more interested in comfort when it was launched 127 years ago, efficiency is part of comfort. We set science-based targets to reduce Scope 1 and 2 greenhouse gases, which are the emissions our manufacturing plants emit, by 37.5 percent, and to reduce Scope 3 emissions by 30 percent per product sold.

“Scope 3 emissions are important from a consumer point of view because ours come from the electricity and natural gas our customers use when they use our equipment,” she said.

Meanwhile, multifamily developers and owners should adjust their capital plans around the changes in the HVAC arena, especially in light of current inflation and supply chain issues that may make parts, components and even refrigerants difficult to source in the future. Consultants suggest that if owners foresee future system replacements or scheduled renovations, they should perform them before January 1. It also means developers with sites under construction might want to order and install the HVAC systems before the end of the year.

Author Wendy Broffman